Rapid Prototyping and Multi-Material 3D Printing

Rapid Prototyping and Multi-Material 3D Printing

-by-ES-Technology--tojpeg_1534957206556_x4-1.jpg)

Concept Laser Mlab Selective Laser Sintering (SLS) by ES-Technology

Stratasys Objet 500 Connex 3

EnvisionTEC ULTRA 3SP

Stratasys Fortus 400mc 3D Printing System

NanoScribe Professional GT

Microfab JetLab 2 Printing System

Equipment Introduction

Concept Laser Mlab Selective Laser Sintering (SLS) by ES-Technology

-by-ES-Technology--tojpeg_1534958918894_x2.jpg)

The system is for manufacturing components with elaborate structures. It is perfect when high surface quality and the finest component structures are important. The laser beam resolution of the Mlab cusing is identical to the laser beam resolution of 3D printers.

The system works with a range of materials including titanium and titanium alloys. The machine works on powder materials whose ingredients, geometry and distribution of powder particles are specially tailored for the technology and the process. All powder materials can be sieved and reused after each build.

Stratasys Objet 500 Connex 3

The system offers three-material jetting technology that automates the creation of complex prototypes that have diverse material properties – no assembly is required. With extensive true-to-life colour options, it can integrate vibrant colours into multi-material models.

The Connex3 includes a wide range of flexible rubberlike options, which can be combined with rigid materials in one build. It can prototype rubber overmolding and soft, non-slip surfaces such as buttons, handles, grips and any number of flexible details.

It builds clear models or transparent/opaque combinations – including opaque model interiors with transparent exteriors – along with a wide range of translucent colours. We also have Object Connex 260 and Eden 350 available within the Hamlyn Centre.

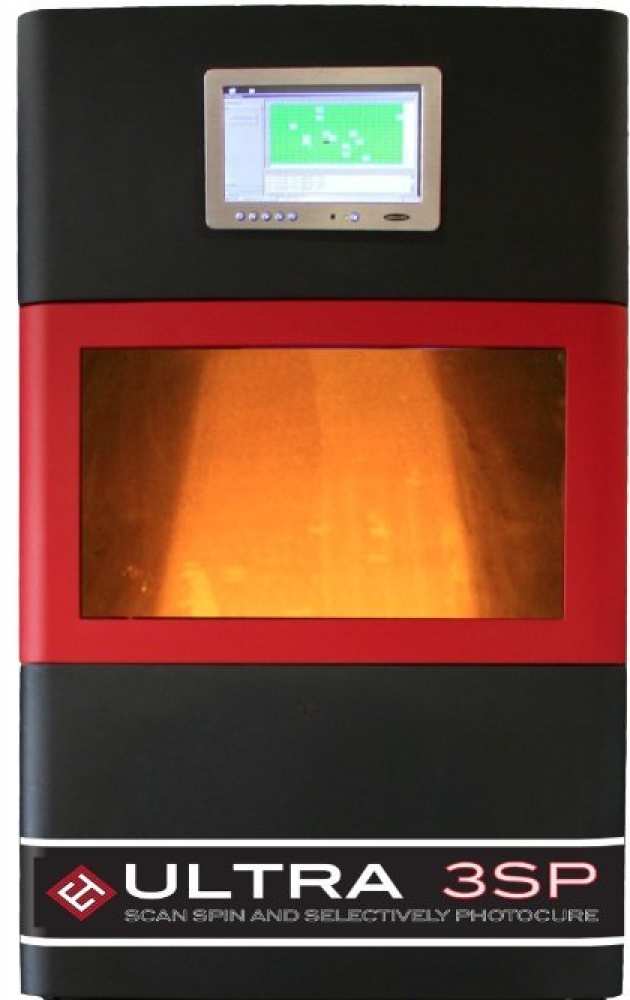

EnvisionTEC ULTRA 3SP

This printer can quickly 3D print highly accurate parts from STL files regardless of the geometric complexity. A single material is used for both build and support.

The system uses layerless technology with no stair stepping on inner and outer surfaces. Printing is possible at speeds as high as 10 mm per hour for a full envelope, or 20mm in 2 hours for a full envelope at a 50 micron resolution.

Stratasys Fortus 400mc 3D Printing System

The Fortus 400mc produces accurate, durable, repeatable 3D parts with superior throughput. It builds parts as large as 406 x 355 x 406 mm (16 x 14 x 16 in.) and features two material bays for maximum uninterrupted production.

The 400mc builds in 11 real thermoplastics for applications that require high-performance, biocompatibility, static dissipation or resistance to heat, chemicals or UV radiation. The system offers four layer thicknesses to choose from.

NanoScribe Professional GT

The Photonic Professional GT is a compact laser lithography system enabling true 3D micro- and nanofabrication via two photon polymerisation. It combines two writing modes in one device: An ultra-precise piezo-mode for arbitrary 3D trajectories and the highspeed galvo-mode for fastest structuring in a layer-by-layer process.

The Photonic Professional GT is a compact laser lithography system enabling true 3D micro- and nanofabrication via two photon polymerisation. It combines two writing modes in one device: An ultra-precise piezo-mode for arbitrary 3D trajectories and the highspeed galvo-mode for fastest structuring in a layer-by-layer process.

In combination with its software package, the system is well-embedded alongside a 3D printing workflow and offers a high degree of automation. The system allows for the fabrication of high-resolution photo masks and other direct write applications. It offers a writing area of up to 100 × 100 mm² range and a high-sensitivity microscope camera for real-time observation of the printing process.

Microfab JetLab 2 Printing System

The jetlab II is designed for the laboratory development of jetting processes and materials. The system comes with software controlled X-Y positioning and a 200x200 mm2 substrate size and print area. Z axis control of the printhead height is possible as well as “Print-on-the-Fly” (both axes simultaneously) or “Point-to-Point” printing. Raster and vector printing modes are provided.

The jetlab II is designed for the laboratory development of jetting processes and materials. The system comes with software controlled X-Y positioning and a 200x200 mm2 substrate size and print area. Z axis control of the printhead height is possible as well as “Print-on-the-Fly” (both axes simultaneously) or “Point-to-Point” printing. Raster and vector printing modes are provided.

The system is capable of arbitrary printing resolution and direction and complex print job definition through scripting and control of multiple process functions (e.g. valves, light sources, etc.). A CCD camera is included for drop observation as well as a CCD camera with coaxial illumination for substrate observation.