Micro-Assembly, Imaging and Characterisation

Micro-Assembly, Imaging and Characterisation

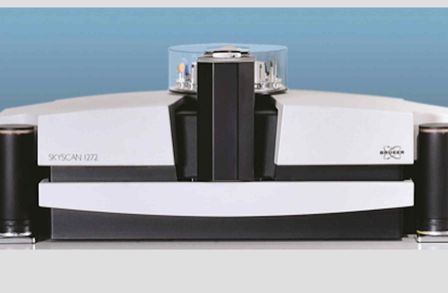

Micro CT Bruker SkyScan 1272

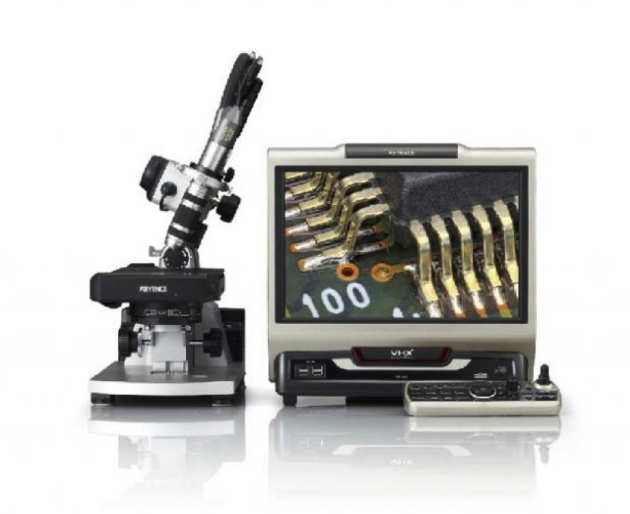

Keyence VHX-2000 microscope

Tescan FIB-SEM Lyra3 XMU

Bruker QUANTAX Energy Dispersive X- ray Spectrometer (EDS)

Manncorp MC-400 Automatic Pick and Place

Flying Probe - Tester SPEA 4020 S2

Carl Zeiss Axio Zoom.V16 Research Zoom Microscope

Multiple Spot Optical Tweezers E3500 Elliot Scientific

Imina MiBot Micromanipulators

Carl Zeiss Multi Coordinate Measurement Machine O-INSPECT 322

Equipment Introduction

Micro CT Bruker SkyScan 1272

The system can non-destructively visualize up to 209 Megapixel (14450x14450 pixels) virtual slices through objects, more than 2600 such slices after a single scan using newly developed 16Mp and 11Mp X-ray detectors in up to three offset positions. Due to phase-contrast enhancement, object details as small as 0.35um can be detected.

The system can non-destructively visualize up to 209 Megapixel (14450x14450 pixels) virtual slices through objects, more than 2600 such slices after a single scan using newly developed 16Mp and 11Mp X-ray detectors in up to three offset positions. Due to phase-contrast enhancement, object details as small as 0.35um can be detected.

The flexible acquisition geometry of the SKYSCAN 1272 scanner is particularly advantageous over intermediate resolution levels, where scans are several times faster (to obtain the same or better image quality) compared to micro-CT systems with a fixed source-detector design.

For any sample, which can be up to 75mm in diameter, the system can automatically optimize x-ray energy and energy filtering using a new maintenance-free X-ray source and automatic 6-position filter changer. Large format imaging is supported by multithreaded GPU-accelerated 3D-reconstruction and realistic visualization by surface and volume rendering.

The system includes a built-in precision micro positioning stage and can scan samples during compression, tension, cooling or heating.

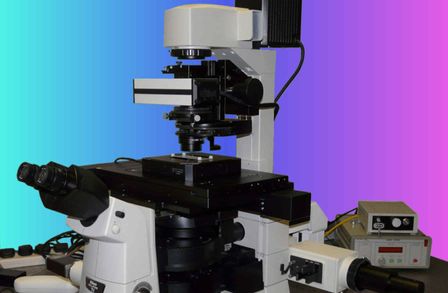

Keyence VHX-2000 microscope

The system is designed to emphasise both high-resolution and depth-of-field. The depth-of-field that is over 20 times greater than that of an optical microscope, with full focus images even at high magnification.

The system is designed to emphasise both high-resolution and depth-of-field. The depth-of-field that is over 20 times greater than that of an optical microscope, with full focus images even at high magnification.

With one button push the lens will automatically scan throughout the range of an object and dynamically compile every in-focus pixel, generating a fully-focused image. The microscope allows easy focus adjustment, X-Y stage movement, rotation and oblique axis motion.

A custom mechanism allows the target to stay centred in the field-of-view, even when the lens unit is inclined or rotated. LED transmitted illumination is standard with the XY motorised stage for the free-angle system. With light that produces consistent brightness, vivid observation is possible from low to high magnification.

In addition to transmitted illumination, it is also possible to use the LED lighting in conjunction with vertical illumination from the lens. The light can be adjusted for each type of illumination, making it possible to perform observation with an optimum balance of light intensity.

Tescan FIB-SEM Lyra3 XMU

Fully PC controlled Field Emission Gun SEM with Schottky FEG emitter in combination with a High Resolution Gallium Focused Ion Beam column and Gas Injection System (GIS) intended for high vacuum and variable pressure/low vacuum operations.

Fully PC controlled Field Emission Gun SEM with Schottky FEG emitter in combination with a High Resolution Gallium Focused Ion Beam column and Gas Injection System (GIS) intended for high vacuum and variable pressure/low vacuum operations.

With high standard optical properties, flicker-free digital image with super clarity, the sophisticated user-friendly software for SEM/FIB/GIS control and image capturing uses Windows platform. The system utilises standard formats of stored images, easy image management processing and measurements, automatic set up of the system and many other automated operations are characteristic features of the instrument.

Unique three lens Wide Field Optics design offering a variety of work and display modes. Column construction allows fully automated column set-up and alignment without mechanical centring elements. External fore pump and below-chamber mounted turbo molecular pump combination obtains vacuum quickly and cleanly. Network operations and built-in remote access and diagnostics as standard, including, low pressure inlet option, and Low Vacuum Detector. The system is integrated with:

- 4 x Kleindiek NanoWorkstation SY-NW-000

- SuperFlat AFM SY-SFAFM-000

- Bruker QUANTAX Energy Dispersive X- ray Spectrometer (EDS)

Bruker QUANTAX Energy Dispersive X- ray Spectrometer (EDS)

The EDS operates at 121 eV at Mn Ka, providing the energy resolution needed to analyse complex samples – especially in the light element and low energy range below 1 keV.

The EDS operates at 121 eV at Mn Ka, providing the energy resolution needed to analyse complex samples – especially in the light element and low energy range below 1 keV.

The system comes with a signal processing unit that allows high pulse processing speeds and guarantees reliable results at any count rate. The processor is capable of over 600 kcps output count rate at more than 1,500 kcps input.

This is valuable because many applications like mapping or particle analysis require high count rates. The EDS’s real-time spectrometry function offers instant information on local sample characteristics. Automation of routine analyses can be set up and performed with the in-built software.

Manncorp MC-400 Automatic Pick and Place

MC-400 places SMDs from 0201 to 100 mm x 150 mm, including BGAs, MBGAs, CSPs and µBGAs, micro lead frames (MLFs), flip chips, ultra-fine pitch to 15 mil and odd-form components.

MC-400 places SMDs from 0201 to 100 mm x 150 mm, including BGAs, MBGAs, CSPs and µBGAs, micro lead frames (MLFs), flip chips, ultra-fine pitch to 15 mil and odd-form components.

On-the-fly and bottom vision alignment systems ensure accurate alignment of component connection points (leads, balls, bumps) to pads, with ±0.05 mm placement accuracy and ±0.01 mm repeatability.

With placement rates of 2,500 cph (IPC 9850), up to 64 feeder slots, and quality components such as X-Y linear encoders and smart feeders, users can move from prototype into production on the same machine, reducing programming and job setup time.

The system’s software will optimize feeder locations and placement sequences to achieve the greatest possible throughput.

Flying Probe - Tester SPEA 4020 S2

The system allows for fast prototype design. The test program generation is fast and allows for quick reporting of the test results to technicians for technical implementations.

The system allows for fast prototype design. The test program generation is fast and allows for quick reporting of the test results to technicians for technical implementations.

The 4020 S2 can be equipped with multiple, independent, asynchronous test cores, each one with dedicated instrumentation and resources. Each X-Y-Z axis is equipped with high force linear motors. This technology provides high speed of movement and positioning stability.

The system’s Multi-Jig Bottom Platform provides a wide range of instruments that enhance productivity and test capabilities: fixed probes, board support, mini-fixture, cable connection and the exclusive Self-Adapting Board Support Grid. Along with the Multi-Core Architecture, the Multi-Jig can work simultaneously with the 4 top flying probes.

Carl Zeiss Axio Zoom.V16 Research Zoom Microscope

Provides a magnification range by eye of 7x – 168x with 10x eyepieces of 11.2x – 270x with 16x eyepieces. A camera adapter with 1x, 1.6x and 5x magnification lenses is included to provide additional magnification to the camera to match the viewing magnification.

Provides a magnification range by eye of 7x – 168x with 10x eyepieces of 11.2x – 270x with 16x eyepieces. A camera adapter with 1x, 1.6x and 5x magnification lenses is included to provide additional magnification to the camera to match the viewing magnification.

The system is equipped with co-axial illumination, LED ringlight for 1x objective with variable illumination segments and intensity, darkfield ringlight for the ApoZ 1.5x objective and transmitted light LED unit with selectable segment illumination.

System configuration includes fluorescence illuminator with motorised filter turret and three fluorescence filter cubes with filtersets (DAPI, FITC and TRITC type dyes) and high performance 200W metal halide fluorescence lightsource with integrated motorised shutter and liquid lightguide coupling.

Multiple Spot Optical Tweezers E3500 Elliot Scientific

The system is a fully functional computer controlled unit for the multiple spot trapping and manipulation of micron sized particles. It is designed to be attached to high quality commercial microscopes. An optional force measurement feature delivers a Photonic Force Microscope capability.

The system is a fully functional computer controlled unit for the multiple spot trapping and manipulation of micron sized particles. It is designed to be attached to high quality commercial microscopes. An optional force measurement feature delivers a Photonic Force Microscope capability.

The E3500 system comprises an optical module containing the beam steering optics, external laser source, control module with the drive electronics, microscope interface, PC and unique software. The epifluorescence or camera port of the microscope is used to interface with the optical module and a range of interfaces are available, depending on the make and model of microscope.

Beam control is provided by high-speed acousto-optic beam deflectors. The system’s software and control electronics allow for the creation and independent manipulation of multiple optical traps anywhere within the field of view.

Imina MiBot Micromanipulators

The miBot uses piezo actuators with mobile motion technology that makes the miBot both extremely precise and very easy to control. Diverse micro-tools can be mounted on the miBot tool holder, which makes it particularly well-suited for R&D applications in material science, microelectronics and photonics, whenever in situ physical interactions with the sample are sought.

The miBot uses piezo actuators with mobile motion technology that makes the miBot both extremely precise and very easy to control. Diverse micro-tools can be mounted on the miBot tool holder, which makes it particularly well-suited for R&D applications in material science, microelectronics and photonics, whenever in situ physical interactions with the sample are sought.

The miBot manipulator is a mobile micro-robot. This means it moves directly over the surface of the base on which a sample lays and has no mounting screws. The manipulator can therefore be pre-positioned by hand, making it very fast to set-up and reconfigure. Moreover, no movements of the miBot manipulator are coupled. It makes it very intuitive to control, significantly reduces the time to achieve complex manipulation, and eliminates the risk of damaging samples.

Carl Zeiss Multi Coordinate Measurement Machine O-INSPECT 322

The system comes standard with contact sensors – and also includes ZEISS scanning. The optical and contact sensors are integrated, the convenient CALYPSO 3D CAD software merges the measurement data, thus ensuring that users trust in the reliability of their measuring results.

The system comes standard with contact sensors – and also includes ZEISS scanning. The optical and contact sensors are integrated, the convenient CALYPSO 3D CAD software merges the measurement data, thus ensuring that users trust in the reliability of their measuring results.

The O-INSPECT 322 offers scanning as a standard feature, in which the VAST XXT probe enables precision probing with forces in the millinewton range. Therefore, true 3D measurements with form and position statements are possible.

Telecentric optics are elaborate and therefore not used on most optical measuring machines. Unlike conventional optics, the distance to the object is irrelevant in telecentrics: test objects with different material thicknesses in the camera image can always be measured with the right imaging scale.

O-INSPECT comes standard with the 12x telecentric Discovery zoom lens from microscopy, which compensates for these deviations with an additional zoom range. Outstanding image quality is ensured by the lens and the adaptive illumination system which provides transmitted light as well as several reflected lights at different angles, each with red and blue light. The illumination can be perfectly adapted to the form and colour of the test object.